Are you in the automotive industry and looking to streamline your production process for car lamps? Let’s delve into the intricacies of injection molding for clearer insights!

You learn more about us

Precision Engineering:

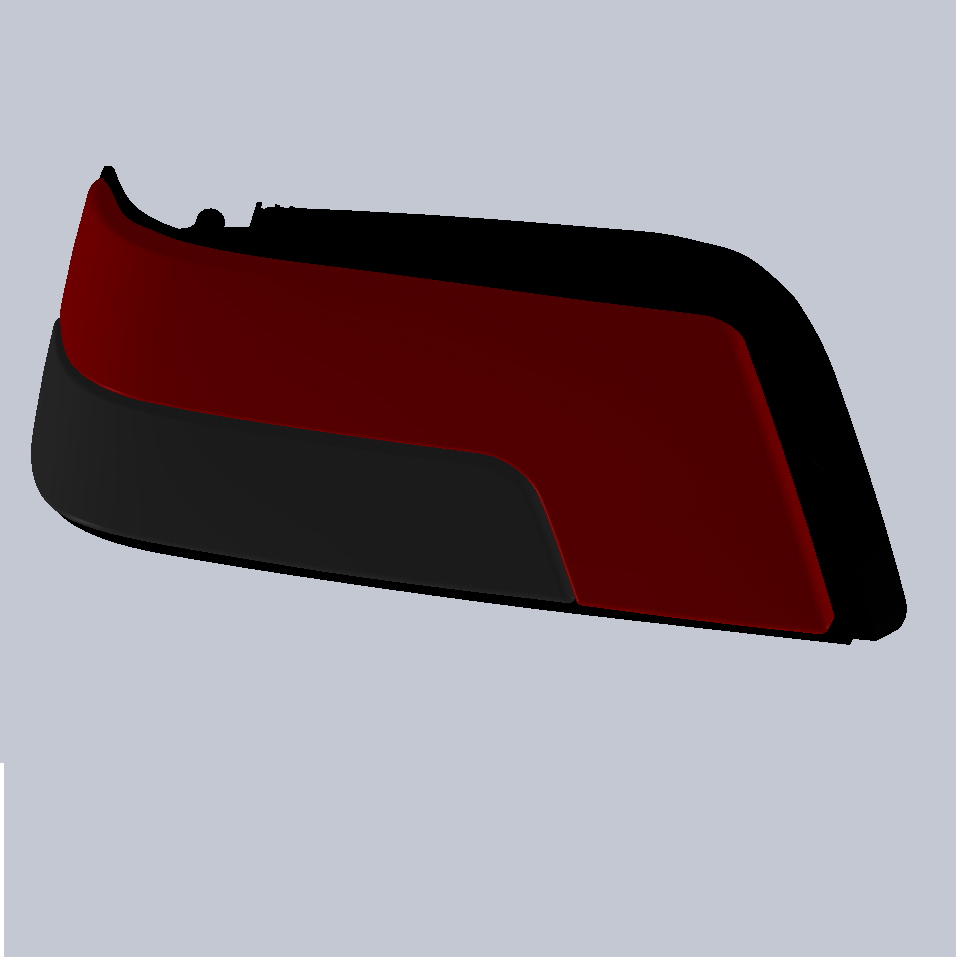

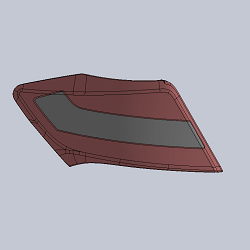

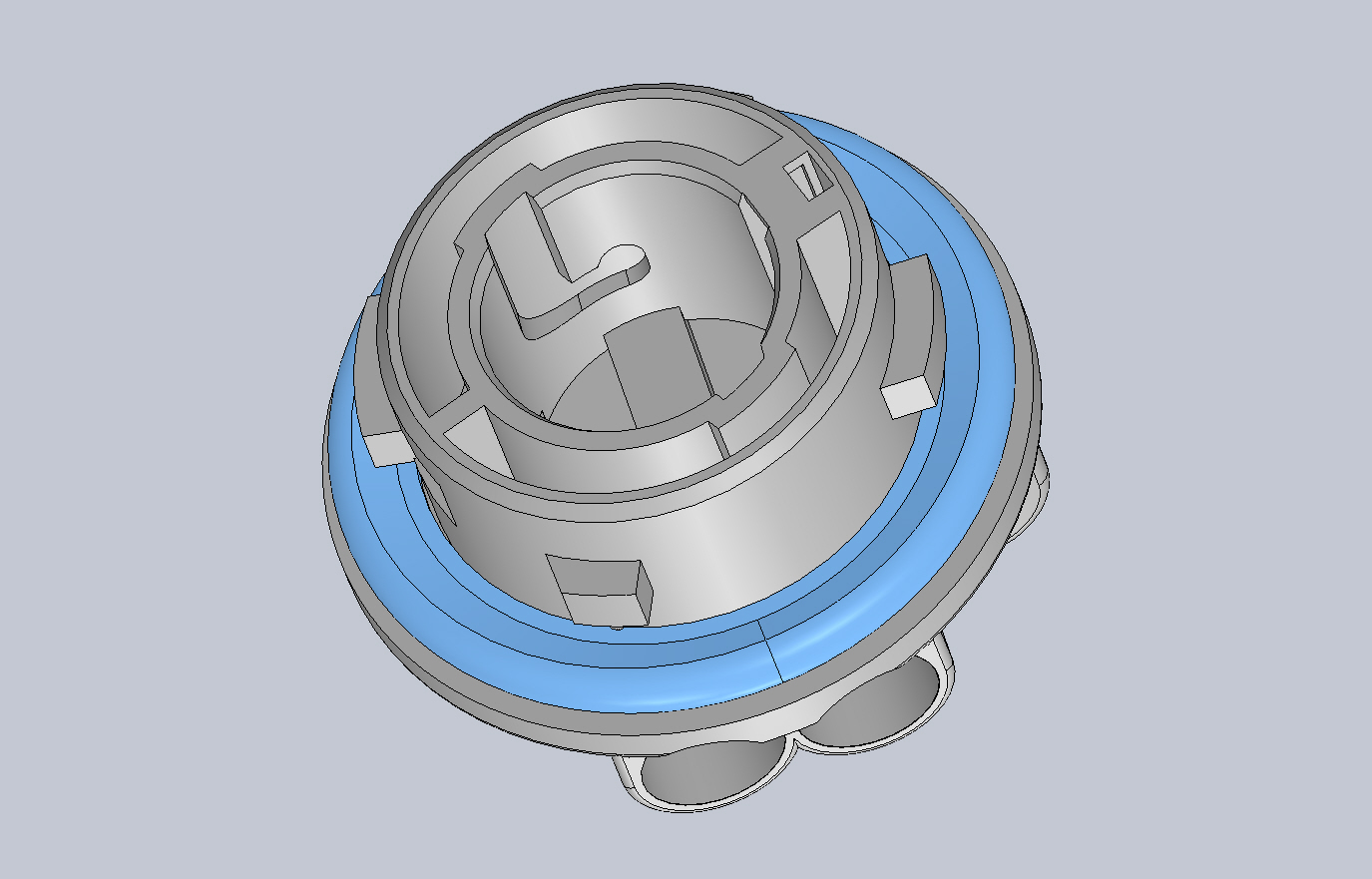

Injection molding is a versatile process where molten material is injected into a mould cavity, cooled, and solidified to form intricate parts like car lamps with high precision.

Our team of experienced engineers utilizes state-of-the-art CAD/CAM software to design intricate molds with precision down to the micrometer. These molds are crafted to exact specifications, ensuring consistent and accurate replication of car lamp components.

We maintain strict tolerance control throughout the injection moulding process, ensuring that each car lamp meets precise dimensional requirements. This attention to detail results in seamless integration with vehicle assemblies and optimal performance on the road.

Quality Assurance:

Rigorous quality control measures are implemented throughout the manufacturing process to guarantee consistency and reliability in every car lamp produced.

🔧 Custom Solutions

Whether it’s tail lamps, headlights, or signal indicators, our custom injection moulding solutions cater to diverse automotive lighting needs, offering flexibility and scalability.

Francesca Piovani

Founder, CEO & Architect

Rhye Moore

Engineering Manager

Helga Steiner

Architect

Ivan Lawrence

Project Manager

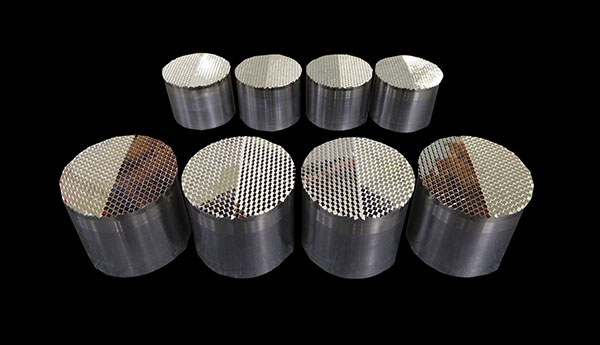

Reflex Reflector Inserts Tools: Engineering Precision for Road Safety

- Custom Tool Design

- High-Quality Materials.

- Tight Tolerance Control